Innovation in Agriculture

Innovation in Agriculture

- Bionic µsoil

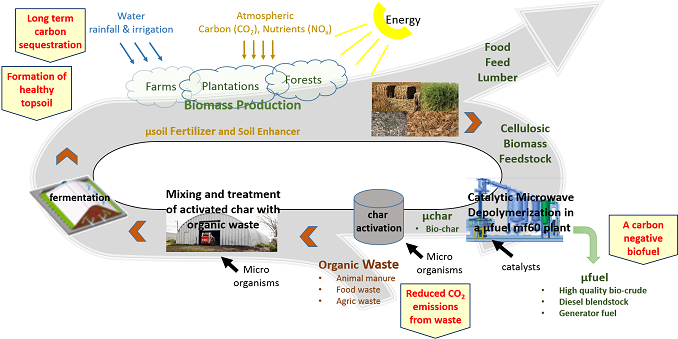

The µsoil organic fertilizer and soil enhancer is Bionic's response to the urgent need for a new, environmentally pro-active commercial agriculture.

A system combining many advantages:

- Clean disposal of manure from animal husbandry

- Organic, superior replacement for synthetic fertilizer

- Avoidance of greenhouse gas (GHG) emissions

- Negative carbon foot print of the system

- Reducing input cost for farmers

- Fully sustainable carbon and nutrient cycles

Overview

Bionic developed a uniquely innovative system for the independent production of a biologic/organic NPK+Ca+Mg fertilizer and soil enhancer for the use in commercial agriculture.

The two central pillars of the system are the combination of Bionic’s activated biochar product, the output of a special microwave assisted pyrolysis process

- bionic µchar, as an ideal substrate carrier for microorganisms like anaerobic bacteria and fungi

coupled with the patented Bio-Elite™ thermophile fermentation process using a mix of

- biomass, including agriculture and food waste, and

- manure from animal husbandry

converted into a high quality commercial fertilizer and soil enhancer.

The outstanding advantage of Bionic µsoil as a fertilizer is an optimal mineral concentration and plant suitability deriving from the unique fermentation process coupled with the top soil forming nutrient and water storage capacity of the activated µchar.

Product features:

- High, normalized concentration of NPK with additional nutrient elements Ca, Mg, C, S and Si

- Fixation of the minerals in an organic complex with very low water solubility resulting in no leaching of fertilizer components into the groundwater and water bodies

- Easy nutrient transfer from the organic complexes to the plant root system via symbiotic fungi

- Significant increase of water storage capability supplied by the highly porous, mineral carrying carbon substrate (bionic char).

- Reduced irrigation requirements.

- Sanitation of animal manure in line with EU standards through fermentation at 75° C

- The product is free of pathogen and soil bound germs

- Complete elimination of antibiotics and hormones from the manure

- Neutralization of pest attractants to certain plants (i.e. rice)

- Up to 60% top soil content loosens up the native soil

- Exceptionally well suited for the reclamation of eroded and depleted soils

- Proven long-term effectiveness as an organic NPK fertilizer

- Reversal of growing fertilizer use requirements

o After 2 years additional use of synthetic fertilizer can be abandoned

o Reduction of fertilizer input cost

- Proven improvement of growth and taste in vegetables and food crops

- Increased protein content in plants

- Up to 2 years shelf life

- No field application limits as for untreated manure

- Odor free, therefore no disturbance of community

- Application with existing equipment

- Product approved in accordance with the German fertilizer regulation

- Numerous scientific test reports available

- All fungi and bacteria used are grown naturally and carry the German/EU Bio-Certificate

Production process and technical parameters

The following major components are required:

a. Biomass including agriculture waste, grasses, straw, under brush, food waste

![]()

pixelio / Christian Roither

a. Animal manure from poultry, pig and cattle farms

![]()

![]()

![]()

pixelio / Adel pixelio / Martin Schemm pixelio / Stefan Schwarz

b. Special Bio-Elite fungi, bacteria and catalyst mix

c. Mechanical production equipment

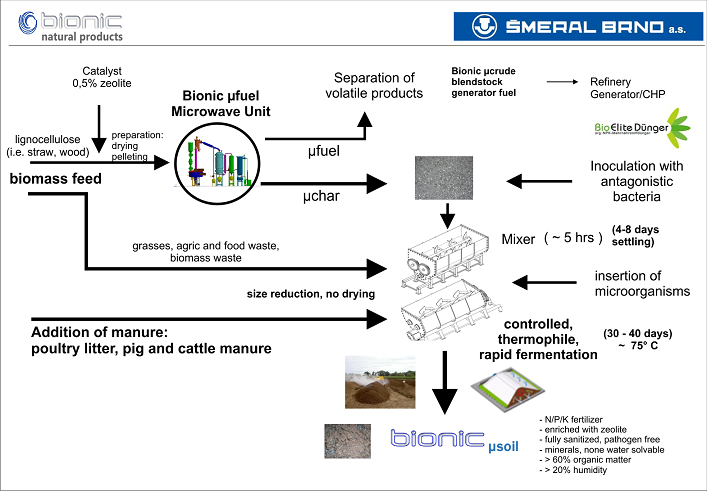

Initially a major part of the available biomass will be dried and mixed with a Zeolite Catalyst (0.5%). The blended mix will be pressed into pellets. The pellets will be processed under vacuum in a bionicfuel microwave reactor at a temperature of approx. 260°C under separation of the volatile ingredients. The output consists of various useful products:

a. A liquid bio fuel which has the properties of light heating oil and can be further upgraded to standard conform transportation fuels

b. Light gases that will be used for internal power generation together with a small percentage of the liquid fuel product

c. Process water containing organic acids which can be purified and has insecticidal properties

d. bionic char, a bio char with uniquely high quality parameters

o a very high heating value comparable to anthracite coal

o a pure carbon content of > 80%

o contains all mineral nutrients from the original biomass feedstock

o shape and form of stable, porous pellets

o completely sterilized due to the microwave processing

The bionic char will be used as a substrate for inoculation with the Bio-Elite microorganism cultures. They multiply rapidly under constant supply of heat and fresh air.

After only 8 days at no less than 15°C the biologically activated bionic char is completed.

In a special mixer the activated bionic char is supplemented with additional biomass and a well-defined amount of manures. The resulting mixture will be continuously agitated for 5-8 hours.

At the end of the above process the resulting mixture is odorless and will be spread out in rots of 2 x 2 x 20 meters where a further ripening process sets in.

While stored in the rots the added bacteria initiate a thermophile fermentation process. Under permanent supply of fresh air and occasional relocation of the rots the fermentation process temperature reaches up to 75°C.

At that temperature level the mass will be sanitized and all sorts of organic toxins (medicine (antibiotics), hormones, etc.) are effectively deactivated.

Throughout the process O2, CO2 and NOX measurements are taken to control and possibly correct the ripening process with various measures.

After a processing time of 40 days the fermentation is completed. In a final step mycorrhizal fungi will be added to improve the nutrient uptake capabilities of plant root systems through a symbiotic effect. Now the product can be stored openly or in bags for future use or sale.

The process flow

Application of Bionic µsoil

µsoil can be applied year round as, being a certified fertilizer product, it is not governed by any regulations limiting the application of manure.

µsoil remains in the upper layers of the soil and helps loosen it. If used continuously it will support a continuous increase of the top soil.

The methods of application depend of course on the type of crop grown.

µsoil can be applied with all traditional agriculture equipment.

Due to a delay in nutrient availability directly after applying µsoil for the very first time application of additional 15% of synthetic NPK is recommended in the first year to maintain prior yields. From year 2 the fields start benefiting from the unique long-term µsoil effects and the use of synthetic NPK can be dropped forever while the superior µsoil properties start showing their impact on quantity and quality of the crops planted.

Due to the water insoluble manner in which nutrients are bound in µsoil the required quantities and concentrations for application cannot be compared to the prior use of synthetic fertilizers. Rather, since unused nutrients are not permanently leached from the higher soil levels by rain and irrigation, they remain available to following crops just like the natural nutrients present in virgin soil would do. Thus with the continuous use of µsoil a completely new balanced nutrient cycle is established in the soil. Only nutrient quantities used by the plants during one crop season need to be replaced for the next.

At least 6-8 weeks prior to a first planting season using µsoil a quantity of 1.5 - 2 MT/ha should be applied and worked into the soil at a depth of 10-15 cm. In regions with a cold winter season this is best done in fall before the first frost sets in.

Additional 500 kg/ha should be applied by broadcasting 2-4 weeks after germination is complete. Earlier application might lead to excessive fertilizer damage.

In case of strong nutrient uptakers like vegetables or lettuce 500 g/plant should be used after the seedling is fully developed.

µsoil can be applied very effectively to rice fields since it settles on the ground and the nutrients do not resolve in water. Significant yield improvements are possible while at the same time the rice beetle can be controlled.

The advantages of the Bionic µsoil system

Superior agronomic properties compared to synthetic and other organic fertilizers:

- Certified organic agriculture without the usually expected yield reductions

- Exploitation of the elevated national and international price levels for organic products (15-30%)

- New export opportunities to advanced markets like the EU

- Immediate cost reduction for field inputs increasing further in years 2 & 3

- Long term benefit reversing the inevitable top soil losses through intensive, contemporary agriculture into a continuous process of top soil creation by returning carbon losses to the field

- Soil erosion can be controlled even in extensive mono-culture environments

- Decoupling from exponential price increases in the synthetic fertilizer markets

- Price development of fossil gas coupled to fossil oil

- Some essential resources approaching critical levels globally

- Elimination of an increasingly critical waste management problem

- Elimination of current and future direct cost of manure disposal in animal husbandry operations

- Elimination of the highly critical drinking water contamination with nitrates and phosphates and rising water treatment cost

- Improved public acceptance in the light of growing environmental awareness

Positive environmental impact

- Carbon sequestration allows a negative carbon footprint for a farming operation by removing large quantities from the carbon cycle and storing them for thousands of years

- Significant overall improvement of the greenhouse gas balance by

o avoiding methane emissions from rotting biomass and manure

o reducing the use of fossil gas for fertilizer production

----------------------------------------------------------------

Contact:

![]()

a brand of

Bionic Laboratories BLG GmbH

Spessartsstr. 13, 64859 Eppertshausen, Germany

email: infoThis email address is being protected from spambots. You need JavaScript enabled to view it.