About Us

Bionic Laboratories BLG GmbH is part of the Bionic Group and is among the technological pioneers in the industrial application of microwaves the Technology Provider for the depolymerization and pyrolysis of organic materials. Based on Bionic's IP and its own reactor technology and catalysts, we convert biomass, plastic waste, scrap tires, and refinery residues into high-quality oils, gases, and carbon fractions that can be used both as energy carriers and as the basis for new materials.

Of particular importance is our Bionic µSoil process, which not only produces fuels from biogenic residues but also a highly effective organic fertilizer that acts as a CO₂- sink. This allows for the realization of a CO₂-negative system that combines alternative fuels and soil improvement with climate protection.

Who We Are

Bionic Laboratories BLG GmbH, based in Eppertshausen (Germany), is the central technology provider unit within the Bionic Group.

Our company history now includes over 15 years of Bionic Laboratories BLG GmbH and around 20 years of the Bionic Group – shaped by research, pilot plants, and industrial projects in the field of microwave technology, bioenergy, and biochar applications.

Our team combines engineering, natural sciences, and practical operating experience. On this basis, we develop scalable plant concepts that range from individual decentralized units to larger cluster solutions and can be integrated into existing infrastructure.

Whats Scientists say about us

What We Do

At the core, we work with in-house developed microwave reactors in which organic materials are thermochemically converted in a low-oxygen environment. The combination of microwave energy and suitable catalysts produces defined product streams: oils, gases, and stable biochar. These products form the basis for various applications – from fuels and process energy to fertilizers and soil enhancers, and filter and adsorbent materials.

Several product lines are based on this technology platform, including:

- Bionic µFuel – Conversion of biomass and residues into oil, gas, and biochar.

- Bionic µSoil – Production of an organic fertilizer and soil enhancer based on biochar.

- Bionic µTyre – Processing of scrap tires into light oil, gas, and carbon fractions.

- Bionic µSorb – Use of biochar as a high-performance adsorbent for water and air purification.

Additionally, we are working on CO₂-/NOₓ-/NH₄ reduction concepts as well as on digitalization and AI-supported process control to further increase the efficiency and availability of the facilities.

Our Ambition: Technology, Sustainability, and Economic Viability

Our goal is to develop robust business models from biogenic residues, waste, and difficult material streams that combine technical feasibility, economic viability, and ecological impact. The µSoil approach is a prime example of this: biogenic input materials are processed into fuels and biochar, which in turn forms a stable, humus-like soil enhancer that sequesters carbon long-term in the soil.

In doing so, we address several challenges simultaneously:

- Reduction of waste and nutrient surpluses in the agriculture,

- Substitution of fossil energy carriers with high-quality, renewable products,

- Building up and protecting fertile soils,

- Creation of permanent CO₂- sinks via biochar and µSoil systems.

Responsibility and Corporate Governance

As a company, we recognize our responsibility towards customers, suppliers, employees, and other stakeholders. The basis for this is an internal Code of Conduct that defines expectations for shareholders, management, and employees and sets out our obligations towards our business partners and the public.

Building on this, we develop binding rules for topics such as integrity in business transactions, handling of environmental and safety requirements, data protection, and transparency in communication. The goal is to always combine technological innovation with responsible action.

Location & Contact

Bionic Laboratories BLG GmbH

Spessartstr. 13

64859 Eppertshausen

Germany

Tel.: +49 6071 9848336

Mobile: +49 1525 3340500

E-Mail:

Further information on our technologies, applications, and publications can be found on this website and in our download area.

Bionic at a Glance

-

What we do

Microwave-based conversion of biomass, residues and waste streams into µFuel (bio-oil/process gas), µChar (active Biochar) and µSoil/µSorb(Eco-Fertilizer). -

Technology

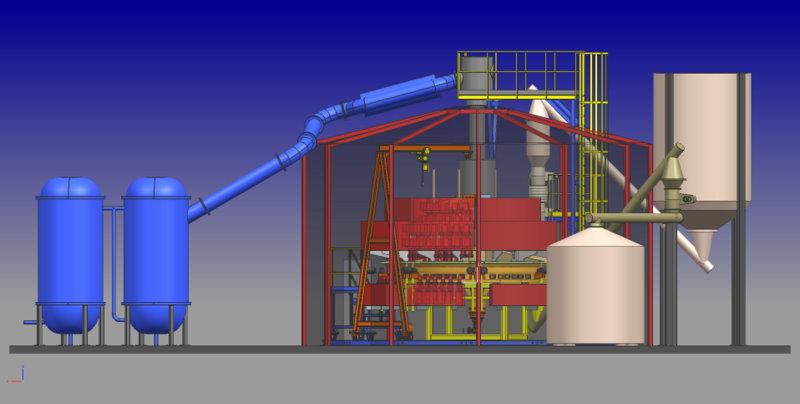

Industrial-scale MWDP (Microwave) reactors (standard type mf200, approx. 1.0 t/h input, scalable in clusters) with AI-supported process control in an inert nitrogen atmosphere. -

Impact

CO₂-negative value chain: combining fossil fuel substitution with long-term carbon sequestration in soils. -

Applications

Municipal waste management, industrial energy and process heat, agriculture and composting, premium activated carbon and filtration solutions. -

Maturity

More than 15 years of development, several pilot and demonstration plants; technology readiness level TRL 7–8 depending on the application. -

Offering

Engineering and technology packages, licensing and project partnerships, µSoil/µSorb products and carbon-credit models.

What Scientists Say About Bionic

Bionic’s microwave depolymerisation technology (“Bionic µFuel / MWDP”) has been investigated, cited and applied in pilot- and full-scale applications by universities, research institutes, industrial partners and authorities for many years. This page compiles the most important external scientific sources and internal expert opinions that evaluate the technology, its products (µchar, µSoil) and its applications.

Bionic on Exhibitions

Contents

- 1. Summary of scientific assessments

- 2. Internal expert opinions & recommendation letters

- 3. Peer-reviewed papers and book chapters referencing Bionic

- 4. Strategic reports & roadmaps (EU / VTT / COST)

- 5. Bionic µFuel / µchar / µSoil documents cited

1. Summary of scientific assessments

The evaluation of all available sources (expert opinions, scientific papers, book chapters, reports, theses and internal technical reviews) leads to a consistent picture:

- Technology: Bionic µFuel / MWDP is classified as a functional, scalable and technologically distinct microwave depolymerisation process that fundamentally differs from conventional pyrolysis.

- Products: Oils (C16–C24 diesel range), process gases (C1–C5) and µchar/biochar are repeatedly analysed and assessed as technically and environmentally usable.

- Environment & soil: Biochar from the Bionic technology can immobilise heavy metals, act as a filter medium (e.g. H2S) and serve as a soil amendment (µSoil) improving soil structure, water holding capacity and soil biology; greenhouse experiments at Mendel University show significantly better water availability and fruit formation in tomatoes under water stress compared to pure substrates.

- Technology readiness: Through HERTY validation (USA), the Brno pilot plant, structural-mechanical calculations of the pressure vessels (ŠMERAL reactor vessel) and peer-reviewed full-scale applications, the technology reaches a readiness level of TRL 7–8 from 2010 and towards TRL 9 with the continous runing 60/90 kW pilot plant (2014).

- Positioning: International reviews (ACS, VTT, COST) list Bionic as an example or reference system for industrial microwave reactors and future-proof biorefinery concepts.

2. Internal expert opinions & recommendation letters (selection)

The following sources exist as PDFs from direct collaboration with Bionic. They evaluate the technology and its products from a process engineering, materials science, agronomic and structural-mechanical perspective.

| Institution / Author | Year | Document | Focus / Key message |

|---|---|---|---|

| HERTY Advanced Materials Development Center, Savannah (USA) | 2010 | Technical validation of Bionic microfuel microwave Depolymerisation System | Independent technical validation of the Bionic µFuel / MWDP technology for US stakeholders. Confirms functionality, process stability and product quality; stand-alone technical due diligence by HERTY with classification in the TRL 7–8 range. |

| BP / Deepwater Horizon Technical Review (Gulf of Mexico) | 2010 | Proposal_BP_Deep_water_horizon_english_may_2010_rev20009.pdf | Independent technical due diligence within the BP Deepwater Horizon technical review. Assesses the possible use of Bionic microwave depolymerisation for treatment and utilisation of oil-containing residues and contaminated materials in the context of the oil spill in the Gulf of Mexico. |

| GNS Halle (Society for Sustainable Material Use) | approx. 2010 | Stellungnahme GNS zum Bionic-Verfahren | Evaluation of test facilities and products. Confirms technically sound operation and clearly defined oil and gas fractions (C16–C24, C1–C5), as well as basic process stability. |

| Innventia / Valmet (Sweden) | 2014–2015 | Feasibility Study Lignin – Bionics, Recommendation Letter | Assesses LignoBoost lignin as an ideal feedstock for the Bionic microwave conversion. Lignin oils from the process are described as energy-dense, aromatic and suitable for refinery integration; clear positive recommendation for continued collaboration. |

| Preem AB (largest refinery operator in Scandinavia) | approx. 2014–2015 | Statement within the lignin feasibility study | Confirms interest in Bionic lignin oils for future fuel and refinery applications; positions the technology as a relevant building block for future biofuel strategies. |

| Stockholm University / EXSELENT Center (incl. Prof. Hedin) | 2015 | Letters & project descriptions | Confirms that Bionic biochars exhibit high BET surface areas and suitable functional groups for applications in adsorption, filtration and energy storage (e.g. supercapacitors). |

| University of Applied Sciences Erfurt | approx. 2007–2008 | Diploma thesis – microwave depolymerisation of scrap tyres | Diploma thesis on the material recovery of scrap tyres using Bionic microwave technology. Investigates the breakdown of complex elastomer structures, product qualities of oil and µchar and key process parameters. Confirms the basic suitability of MWDP for rubber-based problem materials. |

| Brno University of Technology / AdMaS | approx. 2015–2018 | PhD programme – microwave pyrolysis of sewage sludge | Multi-year PhD research on microwave pyrolysis of sewage sludge based on the Bionic plant in Brno. Includes material series, parameter studies, analysis of oils, gases and biochars and forms the scientific basis for the subsequent peer-reviewed publications (e.g. Ševčík et al., Raček et al.). |

| Mendel University in Brno, Faculty of AgriScience | 2016 | Final results of experiment with cultivation of plants in substrates with “biochar” and/or Bionic µSoil | Greenhouse experiments with tomatoes, lettuce and cucumber seedlings in substrates with µSoil and/or biochar at 100 %, 75 % and 60 % irrigation. Shows, among other things, that µSoil variants under reduced irrigation achieve higher plant height, better water holding capacity (LRWC), higher fruit numbers and fruit weights than the commercial substrate; for lettuce the dominant influence of nutrient availability and pH changes caused by biochar is discussed. |

| University of Applied Sciences Erfurt & additional academic partners | various | Assessment FH Erfurt, additional project reports | Positive assessment of Bionic biochar as a soil amendment: improvements in soil structure, water holding capacity and soil biology; no critical contaminant levels in the samples analysed; provides a basis for the µSoil concept. |

| University of West Bohemia, Pilsen / CVTS (for ŠMERAL) | 2010 | Stress analysis of the pyrolysis bin | FEM analysis of mechanical stresses and deformations of the round pyrolysis reactor (“pyrolysis bin”) under internal pressure, temperature and additional loads (microwave emitters). Shows that maximum von Mises stresses in the most critical areas (lid, penetrations, flange transitions) remain below the allowable stresses for the steel used and that there are sufficient safety margins. |

| University of West Bohemia, Pilsen / CVTS (for ŠMERAL) | 2011 | Stress analysis of the pressure container “ŠMERAL” 2011/07 | Extended structural analysis of the inner and outer pressure vessels (Container I/II) of the reactor. Investigates stress distributions, displacements and bolted joints at 10 MPa internal pressure (Container I) and 0.6 MPa (Container II). Recommends allowable stresses of approx. 120 MPa (bulk) and 160 MPa (peaks) and shows that calculated maximum values remain within these safety limits. |

3. Peer-reviewed papers and book chapters referencing Bionic

Several peer-reviewed publications and a book chapter describe the Bionic µFuel / MWDP technology, its plants and products explicitly or use it as a reference in the context of industrial microwave reactors.

| Author(s) | Year | Title | Journal / Volume | Key statement on Bionic / µchar / µSoil | Link |

|---|---|---|---|---|---|

| Federmann, H. | 2018 | Use of microwaves for depolymerisation and pyrolysis of organic materials. Commercial use of microwaves for depolymerisation and pyrolysis of organic materials, biomass, plastic waste, scrap tyres and refinery residues. | In: Recycling und Rohstoffe, Vol. 11 (VIVIS) | Comprehensive book chapter on MWDP / µFuel technology. Describes the development history, process principle, reactor designs and applications of the Bionic technology and positions it in the context of biomass, plastic and tyre recycling. | Chapter (PDF) |

| Ševčík, J. et al. | 2018 | Microwave pyrolysis full-scale application on sewage sludge | Desalination and Water Treatment, 112, 161–170 | Describes a full-scale microwave pyrolysis plant for sewage sludge in Brno, based on the Bionic reactor technology. Analyses oil, gas and biochar products and confirms technical feasibility. | View article |

| Raček, J. et al. | 2019 | Heavy metal fixation in biochar after microwave pyrolysis of sewage sludge | Desalination and Water Treatment, 159, 79–92 | Investigates heavy metal fixation in biochar from microwave pyrolysis of sewage sludge. Shows that heavy metals are largely bound in the carbon matrix – critical for environmental and regulatory questions (fertilisers, construction materials). | View article |

| Hluštík, P.; Novotný, J. | 2018 | The Testing of Standard and Recyclable Filter Media to Eliminate Hydrogen Sulphide from Sewerage Systems | Water, 10(6), 689 | Tests various filter media; one medium is a biochar from the Bionic microwave plant in Brno. Confirms the effectiveness of µchar/biochar for removing H2S from sewer systems. | Article (open access) |

| Korytář, I. et al. | 2022 | Treatment of tunnel wash water: case study from Brno | Desalination and Water Treatment, 271, 27–37 | Case study on tunnel wash water treatment; explicitly cites the “BIONIC Microfuel Brochure – Second Generation Green Fuels from Biomass and Waste” as a technical reference for microwave pyrolysis and biochar use. | Article (open access) |

| Priecel, P.; Lopez-Sanchez, J. A. | 2019 | Advantages and Limitations of Microwave Reactors: From Chemical Synthesis to the Catalytic Valorization of Biobased Chemicals | ACS Sustainable Chemistry & Engineering, 7(1), 3–21 | International review on microwave reactors. Shows the Bionic µFuel mf60 plant as an example of an industrial MW reactor for biomass/waste (including image source Bionic Laboratories). | DOI / article |

4. Strategic reports & roadmaps (EU / VTT / COST)

International technology roadmaps and EU tables list Bionic as an example technology for microwave-based biorefinery approaches.

| Author / Institution | Year | Title | Key statement on Bionic | Link |

|---|---|---|---|---|

| VTT Technical Research Centre of Finland (Ahlqvist, T. et al.) | 2013 | Future options for the cellulosic fibre value chain in the Green Triangle, South Australia | Technology and policy report listing the “Bionic microfuel technology” as an option for converting biomass into light oil using advanced microwave technology. | Report (PDF) |

| COST Action FP0901 | approx. 2011–2012 | Biorefinery activities – technology tables | EU overview of biorefinery activities. States: “Bionic microfuel technology transforms biomass to lightoil using advanced microwave technology” and classifies the technology as catalytic low-temperature depolymerisation. | Table (PDF) |

| Various authors | approx. 2018+ | Economic and Environmental Benefits of Modular Microwave-Assisted Systems | Techno-economic assessment of modular microwave systems; cites the Bionic Microfuel Brochure as a technical reference for MWDP parameters and system configuration. | Overview / abstract |

5. Bionic µFuel / µchar / µSoil documents cited

Several external works rely directly on Bionic technical documentation, brochures and conference contributions. These can – if desired – be offered as downloads.

| Author / Publisher | Year | Title | Focus | External reference | Link / download |

|---|---|---|---|---|---|

| Bionic Fuel Knowledge Partners Inc. / Bionic Laboratories BLG GmbH | approx. 2011–2014 | Bionic µFuel – Catalytic Microwave Depolymerisation (MWDP), Second Generation Green Fuels from Biomass and Waste | Detailed presentation of the µFuel process, mf60/mf480 plants, process flows and product portfolio (µcrude, µchar, µSoil). | Cited in Korytář 2022, economic and environmental analyses, ACS review (mf60 image source). | Slideshare |

| Bruemmer, H. | 2013 | Bionic µFuel Catalytic Microwave Depolymerization (MWDP) – 2nd Generation Green Fuels from Biomass and Waste Materials | Technical report on the MWDP process, reactor concept, process parameters and product qualities. | Serves on ResearchGate and in various project contexts as a reference for MWDP. | ResearchGate |

| Bruemmer, H. | 2014 | Arable Soil for Future Generations | Conference paper on the µSoil concept: use of µchar as a soil-building and CO2 sink instrument (“artificial terra preta”), erosion and desertification control. | Links Bionic µFuel (µchar) with soil fertility and CO2 sequestration. | ResearchGate profile |

| Bruemmer, H. | 2015 | Summary Bionic µSoil – artificial terra preta | Detailed description of µSoil as an organic NPK fertiliser and soil system: combination of µchar, thermophilic fermentation and nutrient recycling. | Serves as a reference for µSoil level concepts and is cited in internal and external projects. | ResearchGate (full text) |

| LignoCity / RISE / Karlstad University | 2019 | Biomass to bio-fuels and bio-carbons by use of microwave enhanced pyrolysis (Master Thesis Work) | Project description for a master thesis on lignin → bio-oil + bio-carbon using MWDP technology, explicitly described as “microwave enhanced catalytic pyrolysis (MWDP) technology developed by Bionic BTL GmbH”. | Confirms that Bionic MWDP serves as a basis for lignin upgrading in Scandinavian R&D projects. | LignoCity / RISE (PDF) |

.jpg#joomlaImage://local-images/Webpics/slider3/mf90b admas (4).jpg?width=5312&height=2988)

.jpg#joomlaImage://local-images/Webpics/slider3/MSV Brno 2 (3).jpg?width=4128&height=2322)