Bionic µFuel – Next-Generation Microwave Conversion Technology

Bionic µFuel is one of the most advanced microwave pyrolysis systems for the thermochemical conversion of biomass, organic residues and complex waste streams. The technology converts these feedstocks into high-value products such as bio-oil, process gas and biochar.

The process is designed for maximum efficiency, stability and scalability and combines innovative reactor technology with AI-based process control. This makes Bionic µFuel an ideal solution for industrial decarbonisation, circular economy concepts and sustainable energy generation.

What is Bionic µFuel?

Bionic µFuel is a microwave-driven thermochemical conversion process that operates in an inert nitrogen atmosphere. Unlike conventional externally heated pyrolysis, µFuel uses volumetric microwave heating: the biomass is heated evenly from the inside out.

Woodpellets, Biooil, Biochar. Pellet before and after processing.

This results in:

- fast and precisely controllable heating rates

- minimal hot spots and cold zones inside the reactor

- very efficient energy transfer into the material

- stable and reproducible product properties

A key element is Bionic’s specially developed microwave control technology. Power level and field distribution are dynamically adapted to the dielectric properties of the feedstock. This optimises the coupling of microwave energy into the material, leading to more uniform processes, higher yields and better controllability with varying input materials.

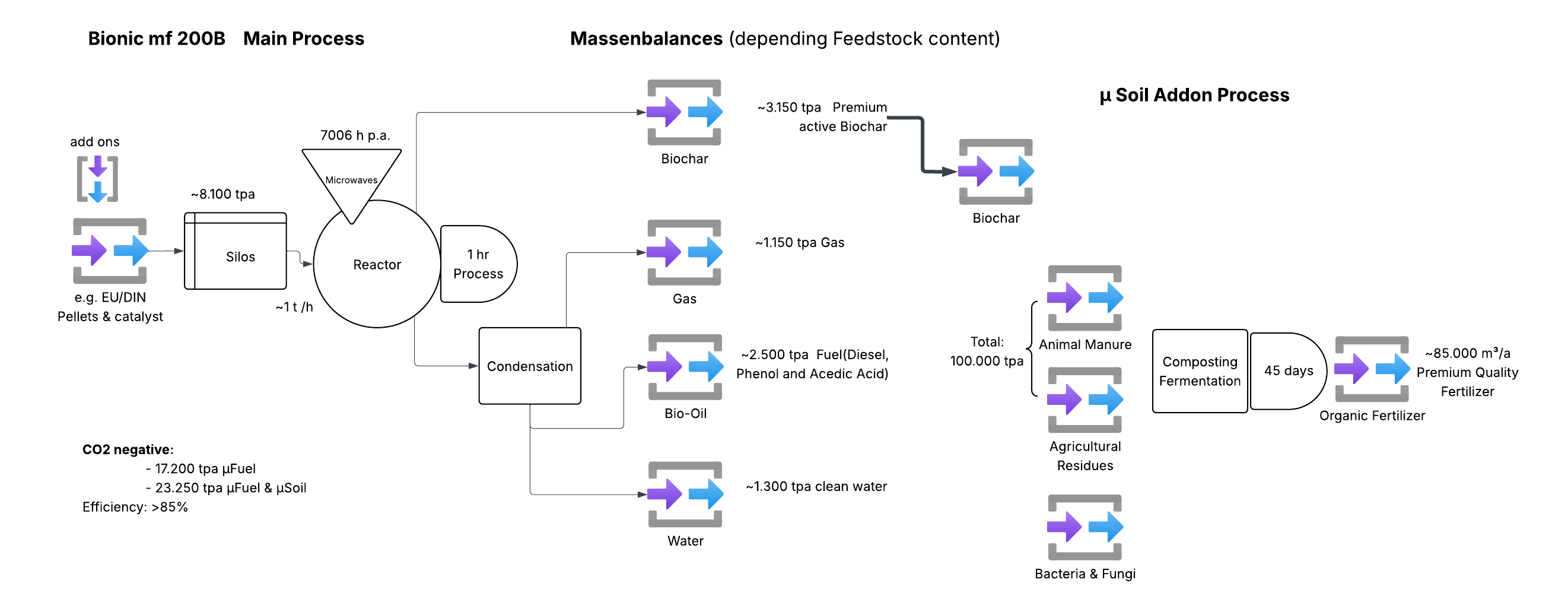

How the µFuel process works

Inside the µFuel reactor, biomass is exposed to targeted microwave energy. The electromagnetic radiation excites the molecules in the material, causing rapid heating and thermal decomposition. This produces three main product streams:

- Bio-oil: renewable hydrocarbon fractions that can be used for energy generation, heating purposes or as a feedstock for the chemical industry.

- Process gas: a combustible gas containing hydrogen, CO and light hydrocarbons, ideal for covering the internal energy demand of the plant.

- Biochar: a stable, carbon-rich solid used in products such as µSoil (soil enhancement), µSorb (filter media) or as a base material for activated carbons and other advanced carbon products.

The system typically uses pelletised biomass (e.g. wood pellets) that has been blended with a special catalyst prior to pelletising. This enables the production of functionalised biochars with specific dopings – for example for sorption applications, filtration media or high-end carbon materials.

The µFuel reactor automatically adapts to variations in moisture content, density and composition of the feedstock. This ensures consistent product quality even with fluctuating input streams.

Bionics Demonstration plants

Precision condensation and filtration

An electrically calibrated, five-stage condensation system combined with electrostatic filters enables very precise control of the quality of liquid and gaseous product fractions. The entire plant is fully parameterisable, allowing product composition and operating points to be set and reproduced reliably.

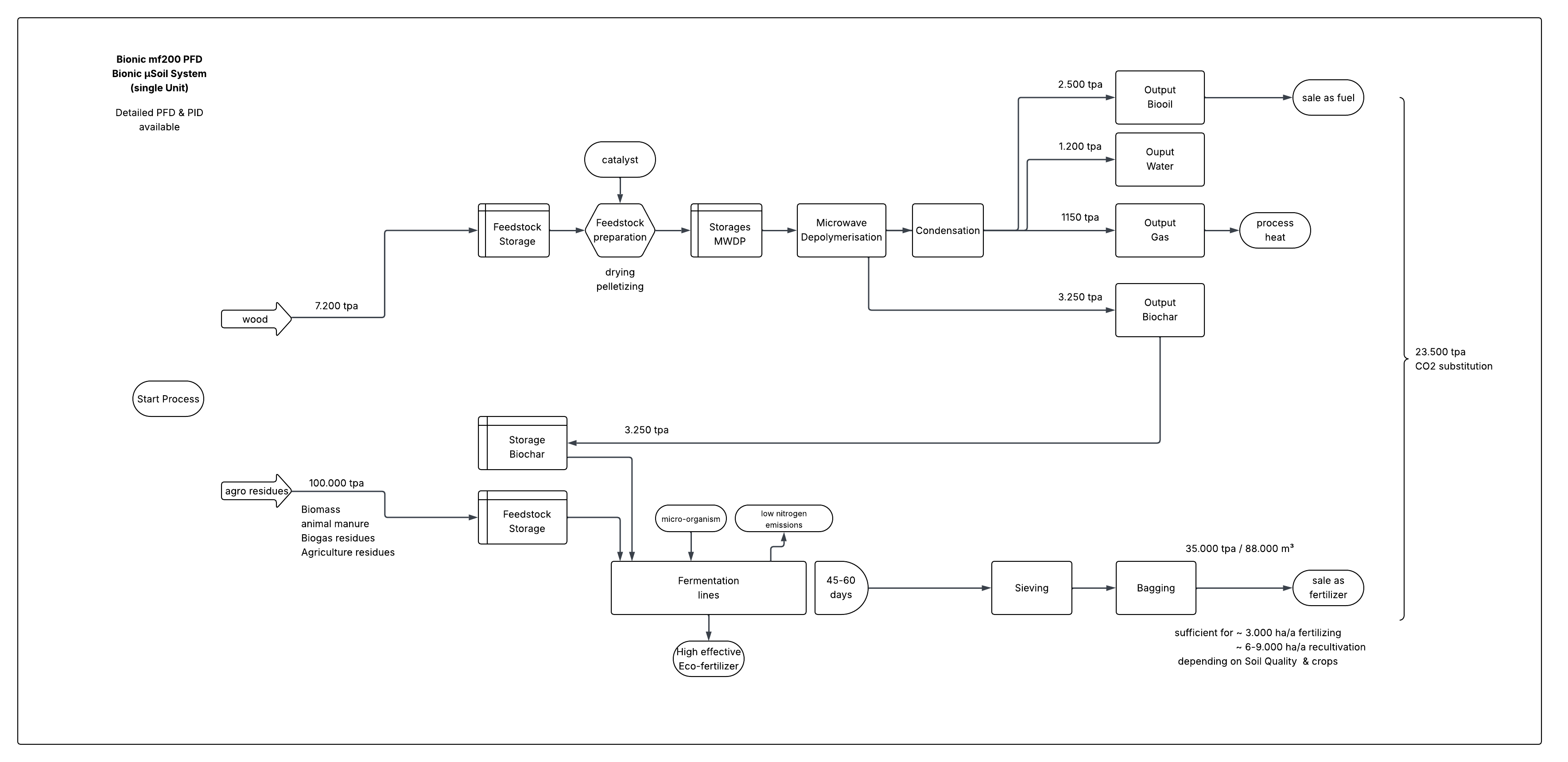

Plant size, capacity and configuration

The standard machine size is the mf200 with a typical throughput of 1.0 t/h of input material. Excluding external tanks and storage silos, a standard plant has a compact footprint of around 600 m² and a maximum building height of approximately 12 m.

Bionic µFuel can be deployed in different configurations:

- Standalone plant: for single sites or decentralised applications.

- Cluster plant: several mf200 units are interconnected as a modular plant cluster to achieve higher throughputs or redundant operating concepts.

For 24/7 continuous operation in a 5-shift model, typically around 20–30 staff are required – depending on site conditions, degree of automation and integration into the surrounding infrastructure.

The modular concept simplifies stepwise capacity expansion and makes it easy to adapt to different feedstocks and market situations.

More about Bionic mf200B

AI-based process optimisation

Bionic µFuel integrates optional Artificial Intelligence and predictive analytics to ensure precise, industry-grade process control. Real-time data from temperature measurements, gas analytics, drive systems and microwave power are continuously analysed. This enables:

- automatic adjustment of temperature and power profiles

- optimisation of bio-oil yield and quality

- production of particularly stable, high-quality biochars

- fast response to fluctuating input materials

- energy-efficient and cost-optimised plant operation

The result is a stable, scalable and highly efficient conversion process designed explicitly for industrial continuous operation.

Industry 4.0: Predictive maintenance & remote monitoring

With integrated machine learning models, µFuel systems detect anomalies long before they cause unplanned downtime. The AI identifies early-stage patterns typical for:

- incipient wear on bearings and drives

- coking and material deposits

- blockages in the material feed or discharge

- thermal overload situations

- unusually rising energy consumption

Together with comprehensive remote monitoring, µFuel plants are fully Industry 4.0-ready:

- predictive maintenance

- remote supervision and remote control

- benchmarking and performance comparison across multiple sites (plant fleets)

- central process optimisation from a control centre

Operators benefit from lower operating costs, higher availability and consistent product quality across different locations.

Standards, design and safety

Bionic µFuel plants are designed and manufactured according to established engineering standards and European regulations, including:

- process-critical components made from stainless steel grade 1.4871

- compliance with the EU Machinery Directive

- ATEX-compliant design for relevant zones

- CE conformity of the complete system

- skid-based design for compact, pre-assembled modules and simplified installation

- redundant key components to increase plant availability

- an independent safety control system clearly separated from the process control logic

This safety and quality concept ensures that the microwave pyrolysis plants comply with regulatory requirements and operate reliably in long-term industrial use.

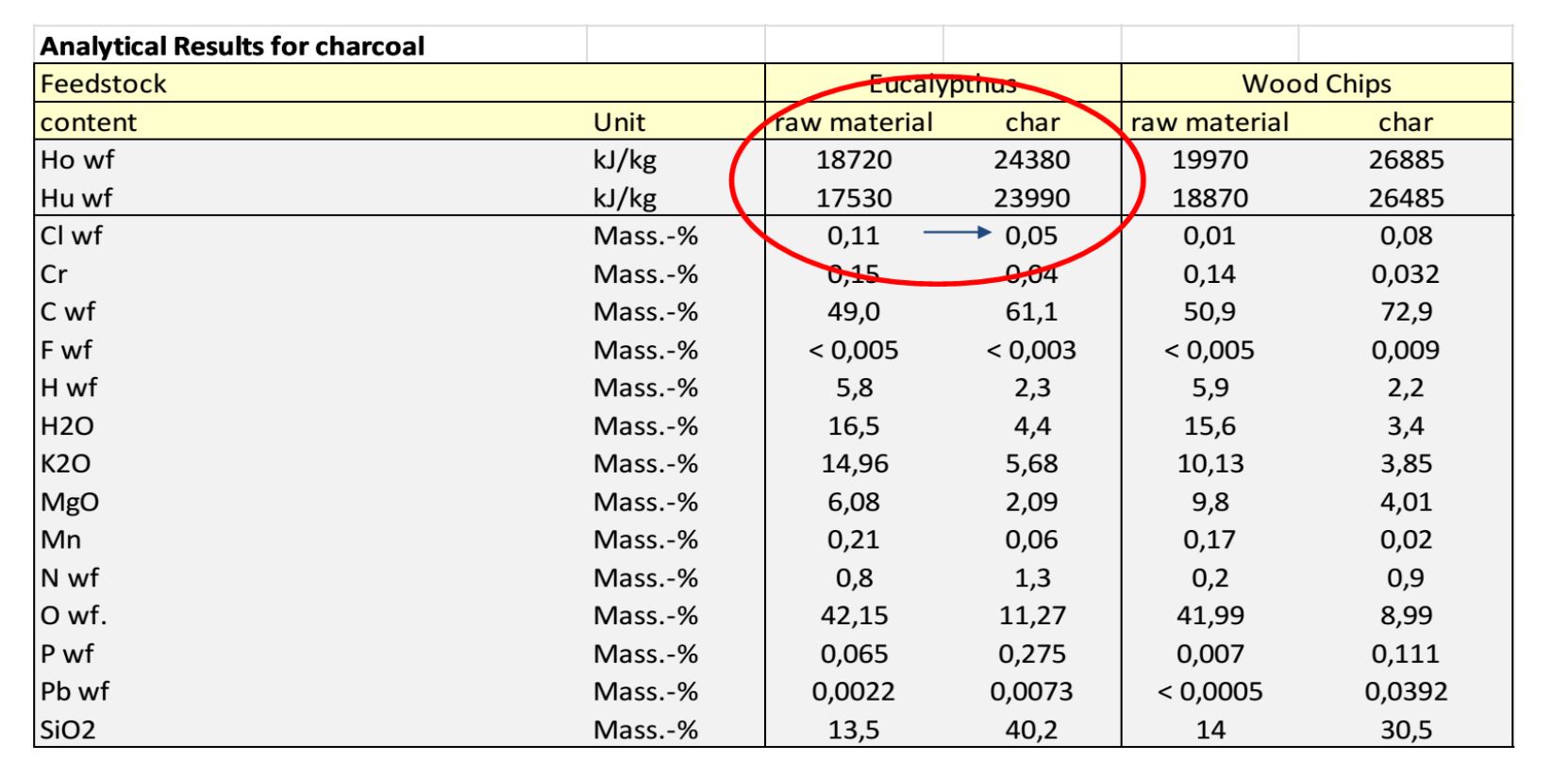

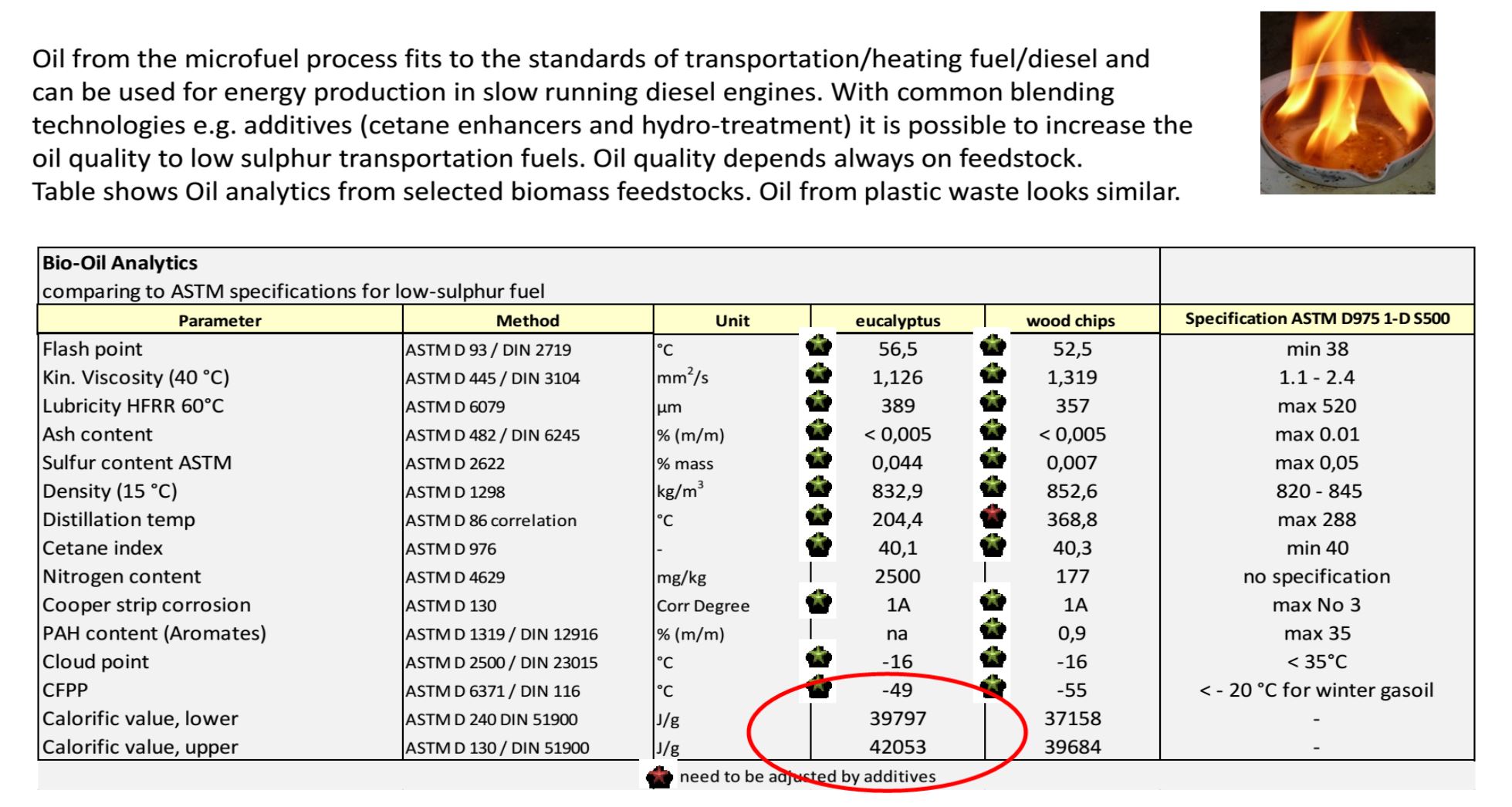

Quality of the Endproducts (sample Biomass/Woodchips)

Optimized Oil

Remark: Oil optimized, biochar usable as byproduct for Soil enhancer

Why Bionic µFuel is future-proof

Bionic µFuel addresses the growing demand for sustainable carbon technologies by combining efficiency, flexibility and long-term stability. The system offers:

- high product yields with consistent quality

- low emissions and a clean conversion chemistry

- high flexibility for different types of biomass and residues

- a modular and scalable plant design (standalone or cluster)

- economic and environmental benefits at the same time

Conclusion: Microwave pyrolysis for decarbonisation & circular economy

Bionic µFuel represents a new generation of microwave-based biomass conversion in an inert nitrogen atmosphere. With its dedicated microwave control technology, catalyst-supported feedstock preparation, AI-driven process control, precise condensation and filtration systems, robust plant design and full Industry 4.0 capability, µFuel turns biogenic residues into:

- renewable energy in the form of bio-oil and gas,

- stable carbon materials such as biochar and activated carbon,

- measurable climate benefits through long-term carbon sequestration.

This makes Bionic µFuel one of the technologically leading and future-ready solutions for sustainable resource utilisation, industrial decarbonisation and a modern circular economy.