Bionic µChar – High-Performance Carbon from the Microwave Process

1. What is Bionic µChar?

Bionic µChar is the biochar fraction produced in the Bionic µFuel process. In a dedicated microwave reactor, biomass is catalytically depolymerized in an inert atmosphere (nitrogen). This yields three main products:

- an energy-rich bio-oil (µFuel)

- a usable process gas

- a highly stable carbon phase: µChar

Compared to conventional biochar from standard pyrolysis, µChar is:

- very carbon-rich and energetically close to anthracite

- treated very homogeneously due to volumetric microwave heating

- equipped with a highly porous surface whose properties are similar to activated carbon

This makes µChar at the same time:

- an effective climate protection tool

- a building block for regenerative agriculture

- a strategic feedstock for modern carbon materials

- a key to the Post Silizium Era

2. Why the Microwave Process Makes the Difference

Microwaves heat the material from the inside out. This enables process windows that are difficult to achieve with conventional flame or contact heating:

- homogeneous heating of the particles

- precise temperature control in the reactor

- gentle surface treatment, as the heat is generated directly in the carbon

For µChar, this means:

- The pore structure can be adjusted in a targeted way.

- Ash content, mineral content and surface chemistry can be controlled more precisely.

- The resulting carbon is stable, highly porous and well “tunable” for different applications.

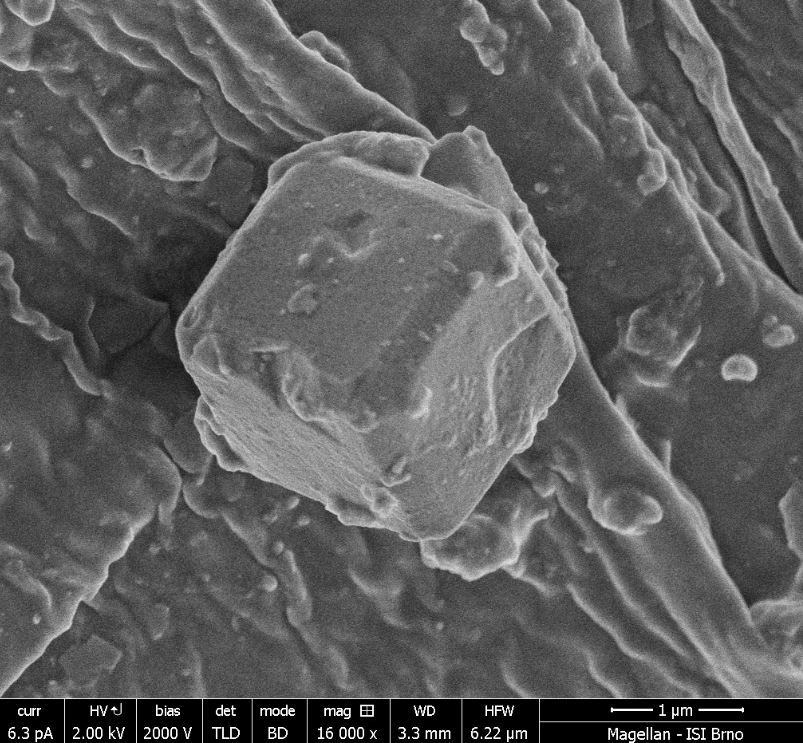

In addition, the process uses a specially designed zeolite catalyst. Zeolites contain a system of extremely fine, precisely defined pores and thus act as a molecular sieve: only molecules of a certain size and structure can enter the pore system and are preferentially converted there. Heavier components and unwanted intermediates are effectively “kept out”.

This molecular pre-selection has several effects:

- Depolymerization proceeds in a more ordered manner and at lower temperatures.

- The resulting oil is more homogeneous and contains fewer by-products.

- The remaining µChar develops more aromatic, ordered carbon structures – an important basis for stability, pore development and later upgrades (activated carbon, supercapacitor materials, etc.).

The combination of microwave heating and zeolite molecular sieve thus creates a particularly efficient, selective process that is designed from the outset for high-quality carbon materials.

3. Climate Protection and Soil – µChar as a CO₂ Sink

3.1. Long-Term CO₂ Storage in Soil

Plants take up CO₂ from the atmosphere and store it in biomass. Normally, most of this carbon returns to the atmosphere through decay or combustion.

In the µFuel process, a portion of the carbon is transferred into µChar. When this biochar is applied to agricultural soils as a component of µSoil, the carbon remains stably bound there for centuries.

A single µFuel/µSoil plant can – based on conservative assumptions – remove tens of thousands of tonnes of CO₂ per year from the atmosphere on a long-term basis. The dominant part of this climate effect resides in the stable carbon matrix of µChar.

3.2. Soil Improvement and Resilience

Beyond its CO₂ sink function, µChar offers additional benefits in soil:

- Water retention: the highly porous structure acts like a sponge and helps retain water in the soil.

- Nutrient buffering: nutrients are bound to the carbon surface and become available to plants on demand.

- Soil structure: the topsoil becomes more stable, less prone to erosion and better aerated.

Through µSoil, µChar is combined with organic components and microorganisms. This supports:

- humus build-up

- more stable yields

- better resilience against droughts and heavy rain events

3.3. Emission Reduction in Animal Husbandry

An additional lever is the use of µChar in animal housing:

- µChar adsorbs ammonia and other emissions early in bedding materials.

- This reduces odour and air pollution.

- The “loaded” carbon brings nitrogen and other nutrients when it is later incorporated into µSoil.

In this way, µChar connects climate protection, animal welfare, emission reduction and efficient nutrient use.

4. From µChar to Value Creation – Upgrade Pathways

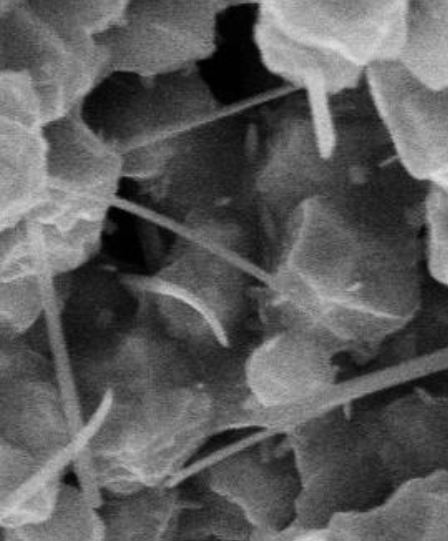

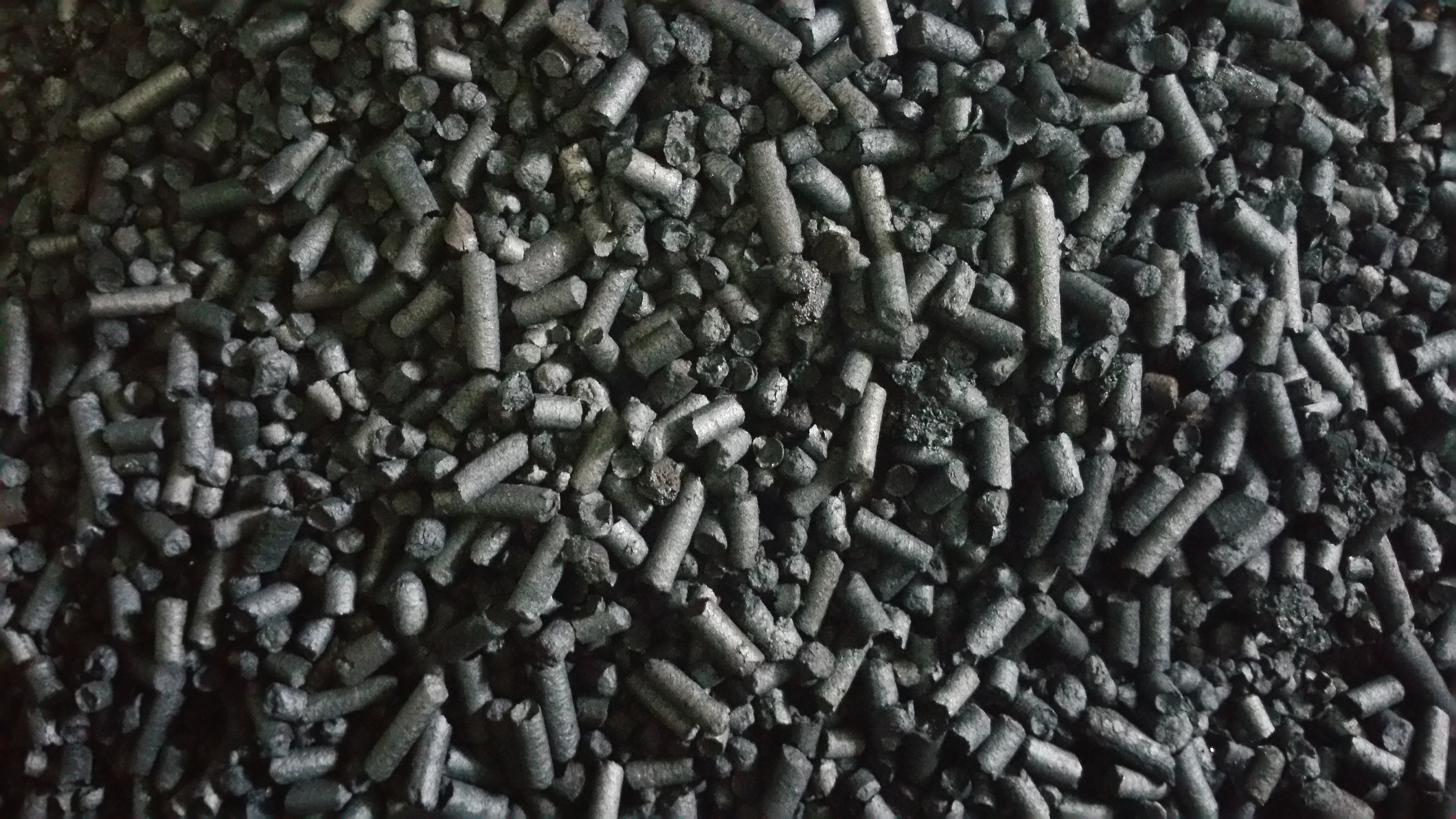

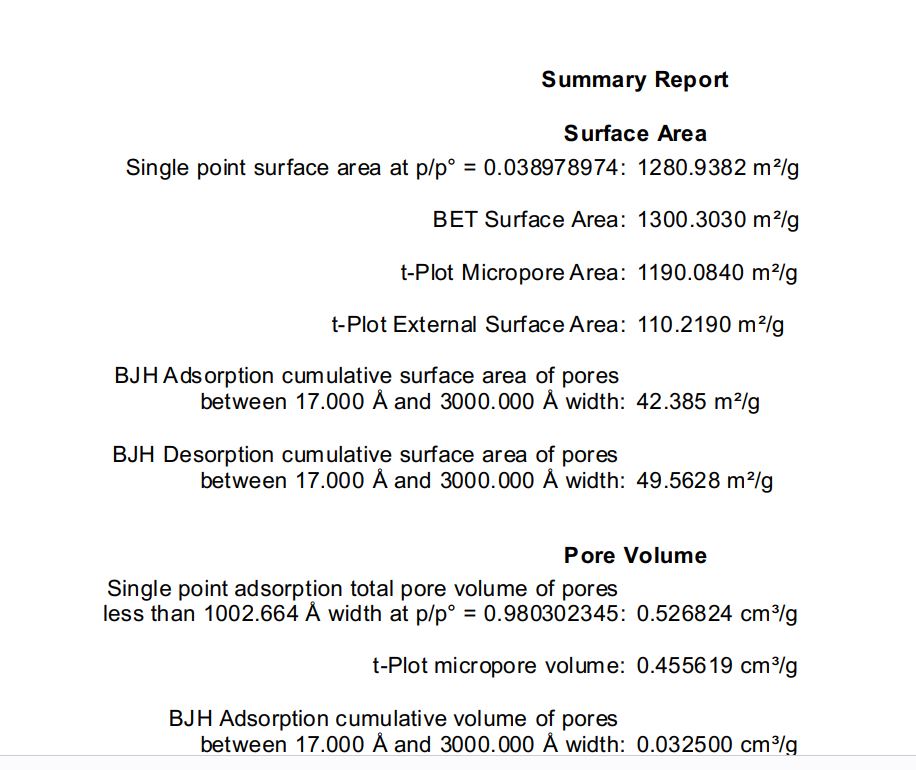

pictures: µChar REM Fotografie, BET Analytics showing Surface and pore volume, catalyst corn inside pore, 1µm resolution, carbon nanofibers / coke fibers with graphene-like domains resolution 200 nm

Bionic µChar is more than biochar in the traditional sense. Due to its highly porous surface – with properties similar to activated carbon – it serves as a platform material for a range of further developments that open up new markets and additional value creation.

4.1. Activated Carbon – Direct Entry into Established Markets

Through an additional treatment step (activation), µChar can be converted into a high-performance activated carbon.

Typical application fields include:

- treatment of drinking and process water

- cleaning of industrial wastewater

- exhaust air and gas purification (e.g. solvents, odours, VOCs)

- odour control in waste management, food industry and agriculture

Key advantages:

- replacement of conventional, often fossil-based activated carbons

- biogenic and CO₂-negative origin

- recurring demand due to regular replacement or regeneration

The existing highly porous surface of µChar provides an ideal starting point for this.

4.2. High-Performance Filtration for Micropollutants

A particularly sensitive field of application for µChar-based activated carbons is the removal of micropollutants from water, including:

- pharmaceutical residues from commonly used drugs (e.g. painkillers, blood pressure medication)

- antibiotics and their metabolites

- hormones (e.g. from contraceptives or hormone therapies)

- heavy metals (e.g. lead, cadmium, mercury, copper)

These substances occur at very low concentrations but can have long-term effects on ecosystems and human health. µChar-based activated carbon can be used in:

- municipal wastewater treatment plants

- industrial and hospital wastewater treatment

- drinking water treatment plants

as an additional treatment step to adsorb exactly these micropollutants.

Another advantage: Thanks to the process design of the Bionic technology, the carbon can be regenerated multiple times. Through thermal or chemical regeneration, most of the load can be removed and the material reused. This:

- reduces operating costs

- lowers resource consumption

- keeps the overall system ecologically and economically attractive

4.3. “Gas Sieves” – Materials for Energy and Environmental Technology

When the pore structure of µChar is tuned into the ultramicropore range, so-called carbon molecular sieves can be created – carbons that separate gases based on their molecular size.

Example applications:

- production of technical nitrogen (PSA systems)

- upgrading of biogas and sewage gas (separation of CO₂ and methane)

- purification of process gases in industrial plants

This allows biogas clusters, green gas concepts and gas grids to be supported and operated more efficiently. A climate protection material thus becomes a building block of modern energy and environmental technology.

4.4. High-Performance Carbons – Membranes and Nanostructures

On a further development level, µChar can serve as a starting point for particularly advanced carbon materials such as:

- carbon membranes for seawater desalination, solvent separation or selective gas separation

- nanostructured carbons (e.g. carbon nanotubes) for electronics, lightweight structures, batteries, specialty filters or composites

These applications are more R&D-intensive but open up access to markets with high value added and strong technology leverage.

4.5. Supercapacitors – Energy Storage with Biochar Electrodes

A dynamic field is the development of supercapacitors. Here, the electrodes are made from highly porous carbon – precisely the domain in which specially produced µChar can play to its strengths.

Key aspects:

- High specific surface area: the larger the internal surface of the carbon, the more charge can be stored. µChar with activated-carbon-like fine pore structures provides this basis.

- Fast charge and discharge: supercapacitors can absorb and release energy within fractions of a second – ideal for peak loads, recuperation (braking energy) or buffers in grids and industrial systems.

- Long lifetime: unlike many batteries, supercapacitors tolerate a very high number of charge cycles with minimal degradation.

With tailored process control and activation, µChar can be turned into electrode materials that offer high capacitance at moderate voltages, good electrical conductivity and can be combined in modular systems.

Thus, biochar from the microwave process becomes a key material for fast, robust energy storage systems that complement and relieve conventional batteries.

4.6. Additional Functions Through Doping

µChar can be equipped with additional properties by targeted doping. The highly porous structure acts as a carrier architecture; substances are deposited in or on the carbon and thereby “program” the material.

Possible functional directions include:

- Magnetizable: by incorporating magnetic particles, µChar can be made magnetically separable – for example in filters that can be removed from a medium using magnets.

- Absorbing high-frequency radiation: specific dopants and layer structures enable materials that attenuate or shield high-frequency electromagnetic radiation (e.g. radar, mobile communications, EMC applications).

- Insulation material in composite panels: µChar can be used in sandwich or composite panels as a combined thermal and acoustic insulation layer with low weight.

- Flame-retardant impregnated: suitable impregnations can increase fire resistance, making µChar-based materials attractive for applications close to the building sector.

- Ultra-fine pigment: finely ground µChar can serve as a deep black pigment in paints, plastics, inks and coatings.

- Medical and cosmetic uses: in highly pure, defined quality, µChar – similar to activated carbon – can be used in medical and cosmetic products, e.g. in masks, filter pads or adsorptive formulations.

The combination of porous structure and tailored doping results in a family of functional materials ranging from environmental applications and energy storage to highly specialized markets.

Pressplatten mit Biochar, Flammresistent

5. Strategic Perspective – More Than Just Biochar

Bionic µChar integrates three levels that are usually considered separately:

- Ecology

Negative emissions through long-term CO₂ storage in soil; reduction of nitrous oxide, ammonia and methane; contribution to soil formation, water retention and agricultural resilience. - Economy

Revenues from µSoil, activated carbon, filter materials for micropollutants, supercapacitor materials and specialty carbons; potential for regional value chains from biomass to high-tech carbon; ability to serve both existing markets (water, gas, environmental technology, energy storage) and future markets (membranes, nanomaterials). - Technology & regional development

Building know-how and IP in advanced carbon materials; linking to topics such as energy transition, circular economy, water and resource security; potential for cluster formation where biomass, plant engineering, material development and applications interact.

Each additional µFuel plant increases not only CO₂ sink capacity but also the potential for local jobs, technical specialization and exportable carbon technologies.

6. Conclusion: From Climate Tool to Carbon Platform

Bionic µChar is far more than a by-product of the µFuel process.

- It is a CO₂ store,

- a soil improver,

- a feedstock for activated carbon, micropollutant filtration, gas sieves, membranes and supercapacitors,

- and a starting point for a new generation of tailored carbon materials.

The combination of microwave processing, zeolite molecular sieve, highly porous structure, regenerable filter performance, targeted doping and use in energy systems makes µChar a versatile building block – from fields and water treatment through to high-tech applications.

Step by step, a carbon platform emerges from what began as a climate protection product – bringing together sustainable agriculture, circular economy, water quality, energy storage and modern industrial development with tangible benefits for the climate, soils, regions and future technologies. A possible trace to the post silitium Era.

.jpg#joomlaImage://local-images/Webpics/slider2/mf60B (3).jpg?width=384&height=288)

.jpg#joomlaImage://local-images/Webpics/slider2/mf90B admas (5).jpg?width=5312&height=2988)

.jpg#joomlaImage://local-images/Webpics/slider2/mf90B admas (9).jpg?width=5312&height=2988)